Description

Level sensors type T-20_.F... are approved by the DIBt (German Institute for Structural Engineering) as liquid level limit switches for the overcharge protection of containers for storing water-dangerous liquids.

Technical Data

Connection

- Box

- Ex-Polyester

- Box

- Ex-Aluminium

Properties

- Protection class EN60529

- IP 65

- connection thread

- G2"

- Union nut

- G 2¾"

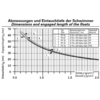

- Guide tube length

- max. 6 m

- Operating temperature

- -20…+60 °C

- Operating pressure

- max. 6 bar je nach Ausführung

- media density

- ρ ≥ 0,72 g/cm³ (je nach Schwimmertyp)

- Switching hysteresis

- 2 mm

- Switching point tolerance

- max. 2 mm

Resistance value

- Operational readiness

- ca. 1 kΩ

- overfill alarm

- ca. 12 kΩ

- Switching time

- ca. 20 ms

- Ex-protection

- siehe Baumusterprüfbescheinigung

- CE marking

- siehe Konformitätserklärung

T-200.F Ex application-specific configuration

T20 - [ 1 ] - [ 2 ] - [ 3 ] - [ 4 ] - [ 5 ] - [ 6 ] - [ 7 ] - [ 8 ] - [ 9 ] - [ 10 ]

product description

Die Magnettauchsonden T20... dienen zur Erfassung von Füllstandsgrenzwerten in Behältern für flüssige Medien, wobei im Gasraum über der Flüssigkeit eine explosionsfähige Atmosphäre der Zone 0 (Kat. 1) und außerhalb des Behälters, im Bereich der Anschlussdose, Ex-Zone 1 (Kat. 2), gegeben ist.

Further product information

The floater switches the reed contact mounted in the guide tube when the liquid level rises. The change in resistance in the sensor circuit resulting from the switching operation is evaluated and the output relay triggered.

Parts of the level sensor which get into contact with the media are completely made of PE, PP, PVC, PVDF. So the level sensors T-20_.F... are perfectly suited for being used with tanks for storing highly aggressive media.

The overfill cut-out device consists of the level sensor and the measuring transducer. Our “contact protective relays” type KR-163... and KR-268..., which are also approved by the DIBt, can be used as corresponding measuring transducers (see section 10). The level sensors T-20_.F... can be connected to our “alarm indicators” type OAA-100 and OAA-300.

- Easy to install

- Sturdy design

- Small dimensions

- Interference-proof measurement

- Switching point adjustable

- Various options for connection (connector box / plug / cable)

- For usage in category 2 (Ex zone 1) (in combination with [Ex]i contact protective relay KR-163/A/Ex)

- Short-line fault / open circuit monitoring (in combination with contact protective relay KR-163... and KR-268... / alarm indicator OAA-100...)

- Under the F-contact further optional switching points can be realized

- Under the F-contact its also possible to integrate a continuous measurement

Documents and Downloads

Settings instructions

Safety instructions

Video of the product

Accessoires

OAA-300

go to product 03.04.2025 13:00 - 13:30

03.04.2025 13:00 - 13:30

03.04.2025 16:00 - 16:30

03.04.2025 16:00 - 16:30